Tuam Tshoj Slaughtering Equipment Chaw tsim tshuaj paus / Halal Slaughter ntawm Tsiaj txhu thiab nqaij qaib

Ua raws li kev ntseeg ntawm "Tsim cov khoom ntawm sab saum toj ntawm ntau yam thiab tsim cov phooj ywg nrog cov neeg niaj hnub no los ntawm thoob plaws lub ntiaj teb", peb ib txwm muab kev txaus siab ntawm cov neeg yuav khoom hauv thawj qhov chaw rau Tuam Tshoj Slaughtering Equipment Chaw tsim tshuaj paus / Halal Slaughter ntawm Tsiaj txhu thiab Nqaij qaib, Peb ua siab dawb cia siab tias yuav pauv thiab koom tes nrog koj. Cia peb txav mus rau pem hauv ntej ntawm tes thiab ua tiav qhov xwm txheej yeej-yeej.

Ua raws li kev ntseeg ntawm "Tsim cov khoom ntawm sab saum toj ntawm ntau yam thiab tsim cov phooj ywg nrog cov neeg niaj hnub no los ntawm thoob plaws lub ntiaj teb", peb ib txwm muab kev nyiam ntawm cov neeg yuav khoom hauv thawj qhov chaw rauQaib Slaughter Machine Line, Tuam Tshoj Slaughter Equipment, Nrog ze li ntawm 30 xyoo kev ua lag luam, peb muaj kev ntseeg siab hauv kev pabcuam zoo tshaj, zoo thiab xa khoom. Peb sov siab txais tos cov neeg siv khoom los ntawm thoob plaws lub ntiaj teb los koom tes nrog peb lub tuam txhab rau kev txhim kho.

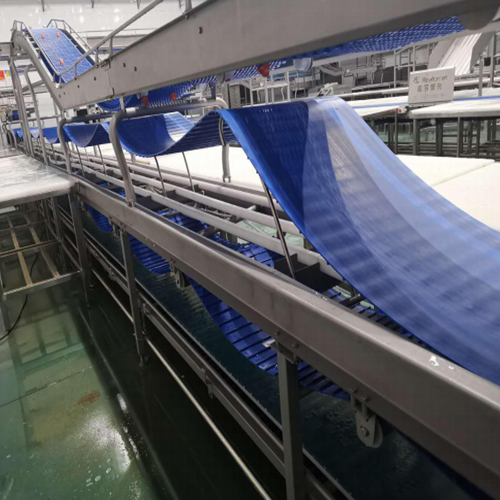

Yaj Slaughter Line

Cov yaj noj qab nyob zoo nkag tuav cov cwj mem → Nres noj / haus rau 12-24h → Da dej ua ntej tua → Shackling thiab nqa → tua → Los ntshav (Lub Sijhawm: 5min) → Sheep Head Cutting → Hind Legs Pre-peeling → Hind Legs Cutting → Pem hauv ntej ceg thiab hauv siab Pre-peeling → Sheepskin tshem tawm → Pem hauv ntej ceg txiav → Rectum sealing → Lub hauv siab qhib → Dawb viscera tshem tawm (Muab lub viscera dawb tso rau hauv lub tais ntawm lub viscera dawb quarantine conveyor rau kev soj ntsuam → ①②) → Trichinella spiralis tshuaj xyuas → Removal viscera Kev tshem tawm viscera (Lub viscera liab yog dai rau ntawm tus nuv ntawm lub viscera liab quarantine conveyor rau kev tshuaj xyuas → ②③) → Carcass Quarantine → Trimming → Nyhav → Ntxuav → Chilling (0-4 ℃) → nqaij txiav → Nyhav thiab ntim → khov lossis khaws cia tshiab → Txias cia → Txiav nqaij rau muag.

① Tsim nyog cov viscera dawb nkag mus rau hauv chav dawb viscera rau kev ua haujlwm. Cov ntsiab lus hauv plab yog thauj mus rau hauv chav tsev khib nyiab txog 50 meters sab nraum lub rooj cob qhia los ntawm huab cua xa khoom.

② Cov pob txha tsis tsim nyog, liab thiab dawb viscera raug rub tawm ntawm kev tua tsiaj rau kev kho mob kub.

③ Tsim nyog viscera liab nkag mus rau hauv chav liab viscera rau kev ua.

Qhov no yog qhov qhia txog tag nrho cov yaj tua kab.

Yaj Slaughter Line

Yaj Slaughtering Line And Process Technology

1. tuav cwj mem tswj

(1) Ua ntej tshem lub tsheb thauj khoom, koj yuav tsum tau txais daim ntawv pov thawj ntawm kev sib raug zoo uas muab los ntawm lub koom haum saib xyuas kev tiv thaiv kab mob sib kis ntawm qhov chaw, thiab saib xyuas lub tsheb tam sim ntawd. Tsis pom muaj qhov txawv txav, thiab lub tsheb thauj khoom raug tso cai kom tshem tawm tom qab daim ntawv pov thawj sib tw cov khoom.

(2) Tom qab suav lub taub hau, muab cov yaj noj qab nyob zoo rau hauv tus cwj mem kom muab tua los ntawm tapping, thiab ua raws li kev tswj hwm kev faib raws li cov yaj noj qab haus huv. Lub cheeb tsam ntawm tus cwj mem yuav tsum tua yog tsim raws li 0.6-0.8m2 ib tug yaj.

(3) Cov yaj uas raug tua yuav tsum khaws cia yam tsis muaj zaub mov rau 24 teev ua ntej xa mus rau kev tua kom tshem tawm qaug zog thaum thauj mus los thiab rov qab mus rau lub cev lub cev. Thaum lub sijhawm so, cov neeg ua haujlwm cais tawm yuav saib xyuas tsis tu ncua, thiab yog tias pom cov yaj muaj mob hnyav, lawv yuav tsum raug xa mus rau cov cwj mem cais rau kev soj ntsuam kom paub meej tias tus kabmob raug xa mus rau chav tua tsiaj thaum muaj xwm txheej ceev rau kev kho mob, thiab cov yaj noj qab nyob zoo thiab tsim nyog. yuav tsum tsis txhob haus dej 3 teev ua ntej tua.

2. Tua thiab los ntshav

(1) Kab rov tav ntshav: Cov yaj nyob tau raug thauj mus los ntawm V-shaped conveyor, thiab cov yaj tau xav tsis thoob nrog cov cuab yeej siv tes ua haujlwm thaum lub sijhawm thauj mus los ntawm lub conveyor, thiab tom qab ntawd cov ntshav yog stabbed nrog rab riam ntawm lub rooj bloodletting.

(2) Cov ntshav tso ntshav rov qab: Cov yaj nyob yog khi rau sab nraub qaum nrog cov hlua khi ntshav, thiab cov yaj yaj yog nqa mus rau hauv txoj kab ntawm cov hlab ntshav tsis siv neeg los ntawm lub hoist lossis cov cuab yeej nqa ntawm txoj kab ntshav, thiab tom qab ntawd cov ntshav. yog stabbed nrog ib rab riam.

(3) Txoj kev tsim ntawm cov yaj bloodletting tsis siv neeg conveyor kab yog tsis muaj tsawg tshaj li 2700mm los ntawm hauv pem teb ntawm rhiav. Cov txheej txheem tseem ceeb ua tiav ntawm cov yaj bloodletting tsis siv neeg conveyor kab: dai, (assassing), draining, tshem tawm lub taub hau, thiab lwm yam., lub sij hawm ntws tawm Feem ntau tsim rau 5min.

3. Pre-peeling thiab sheepskin tshem tawm

(1) Pre-stripping upside down: Siv rab rawg los nthuav ob txhais ceg ntawm cov yaj kom yooj yim rau kev rub tawm ntawm ob txhais ceg pem hauv ntej, nraub qaum thiab hauv siab.

(2) Sib npaug ua ntej stripping: tus nuv ntawm bloodletting / pre-strippin tsis siv neeg conveyor kab hooks ib sab ceg ntawm cov yaj, thiab tus nuv ntawm cov tawv nqaij tsis siv neeg rub conveyor hooks ob sab pem hauv ntej ntawm cov yaj. Qhov ceev ntawm ob txoj kab tsis siv neeg nce qib synchronously. Lub plab ntawm cov yaj yog tig mus rau pem hauv ntej thiab sab nraub qaum, tig mus rau hauv kev sib npaug, thiab ua ntej tawv nqaij yog nqa tawm thaum lub sijhawm thauj mus los. Txoj kev ua ntej stripping no tuaj yeem tswj cov ntaub lo lo rau lub cev thaum lub sijhawm ua ntej stripping.

(3). Clamp daim tawv yaj nrog cov tawv clamping ntaus ntawv ntawm lub tshuab yaj tev, thiab rhuav tshem tag nrho cov tawv yaj ntawm sab nraub qaum mus rau sab ceg ntawm yaj. Raws li cov txheej txheem slaughter, nws tseem tuaj yeem rub tawm ntawm sab xub ntiag mus rau sab nraub qaum ntawm cov yaj. Cov tawv yaj tag nrho.

(4) Thauj cov tawv yaj yaj mus rau hauv chav tsev khaws cia ib ntus los ntawm sheepskin conveyor lossis sheepskin cua conveying system.

4. Carcass ua

(1) Carcass processing station: lub hauv siab qhib, tshem tawm dawb viscera, liab viscera tshem tawm, kuaj carcass, carcass trimming, thiab lwm yam. yog tag nrho cov tiav nyob rau hauv lub automatic carcass processing conveyor kab.

(2) Tom qab qhib lub hauv siab kab noj hniav ntawm cov yaj, tshem tawm cov dawb sab hauv nruab nrog cev, uas yog cov hnyuv thiab plab, los ntawm lub hauv siab ntawm cov yaj. Muab cov viscera tshem tawm dawb tso rau hauv lub tais ntawm cov kab tshuaj xyuas kab mob synchronous rau kev tshuaj xyuas.

(3) Tshem tawm cov kab mob hauv nruab nrog cev, uas yog lub plawv, daim siab, thiab lub ntsws. Dai lub viscera liab tawm ntawm tus nuv ntawm synchronous sanitation kab tshuaj xyuas.

(4) Lub cev yaj yog txiav, thiab tom qab txiav, nws nkag mus rau hauv lub orbital hluav taws xob ntsuas los ntsuas qhov carcass. Kev muab qhab nia thiab stamping yog ua raws li qhov ntsuas qhov hnyav.

5. Carcass ua

(1) Carcass processing station: carcass trimming, rectum sealing, genital cutting, genital cutting, chest open, white viscera tshem tawm, cais tawm ntawm trichinella spiralis, pre red viscera tshem tawm, liab viscera tshem tawm, sib cais, cais tawm, tshem tawm cov nplooj rog, thiab lwm yam,

tag nrho cov ua tiav ntawm cov carcass tsis siv neeg ua kab.Cov kev tsheb ciav hlau tsim ntawm npua carcass txheej txheem kab tsis qis dua 2400mm los ntawm hauv pem teb ntawm lub rooj cob qhia.

(2) Lub dehaired lossis dehided carcass yog nqa los ntawm carcass lifting tshuab mus rau txoj kev tsheb ciav hlau ntawm carcass tsis siv neeg conveying kab, Cov npua dehaired xav tau singeing thiab ntxuav; Tus npua dehided xav tau carcass trimming.

(3) Tom qab qhib lub hauv siab ntawm tus npua, tshem tawm cov viscera dawb ntawm tus npua lub hauv siab, uas yog cov hnyuv, tripe. Muab cov viscera dawb tso rau hauv lub tais ntawm cov viscera dawb quarantine conveyor rau kev tshuaj xyuas.

(4) Tshem tawm cov viscera liab, uas yog lub plawv, daim siab thiab lub ntsws.Hang lub viscera liab tshem tawm ntawm lub hooks ntawm liab viscera synchronous quarantine conveyor rau kev tshuaj xyuas.

(5) Faib cov nqaij npua hauv ib nrab siv hom siv los yog choj hom splitting pom raws tus npua tus txha nraub qaum, ntsug acceleration tshuab yuav tsum tau ntsia ncaj qha saum tus choj hom splitting saw.Small slaughterhouses siv reciprocating hom splitting saws.

(6) Tom qab dehaired npua splitting, tshem tawm pem hauv ntej hoof, rov qab hoof thiab npua tus Tsov tus tw, tshem tawm hoof thiab tus Tsov tus tw yog thauj los ntawm lub laub mus rau lub chav ua hauj lwm.

(7) Tshem cov ob lub raum thiab cov nplooj roj, tshem tawm lub raum thiab nplooj roj raug thauj los ntawm lub laub mus rau chav ua haujlwm.

(8) Pig carcass rau trimming, tom qab trimming, lub carcass nkag mus rau hauv lub khiav hluav taws xob ntsuas yuav tsum tau hnyav. Kev faib tawm thiab foob raws li qhov tshwm sim ntawm qhov hnyav.

6. Synchronous huv tshuaj xyuas

(1) Cov pob txha yaj, cov viscera dawb, thiab cov viscera liab raug thauj mus rau thaj chaw soj ntsuam rau kev kuaj thiab tshuaj xyuas los ntawm kev kuaj xyuas kab mob synchronous.

(2) Cov kab mob uas tsis txaus ntseeg uas tsis ua tiav qhov kev tshuaj ntsuam xyuas yuav nkag mus rau hauv cov kab mob uas tsis txaus ntseeg los ntawm kev hloov thiab rov tshuaj xyuas kom paub meej tias cov kab mob kis mus rau kab mob. Tshem tawm cov kab mob uas muaj kab mob thiab muab tso rau hauv lub tsheb kaw thiab rub tawm ntawm lub tsev tua tsiaj rau kev ua haujlwm. .

(3) Cov viscera dawb uas tsis tsim nyog yuav tsum tau muab tshem tawm ntawm lub tais ntawm cov kab tshuaj ntsuam xyuas kev noj qab haus huv synchronous, muab tso rau hauv lub tsheb kaw thiab rub tawm ntawm lub tsev tua tsiaj rau kev ua haujlwm.

(4) Cov viscera liab uas ua tsis tau qhov kev tshuaj ntsuam xyuas yuav tsum tau muab tshem tawm ntawm qhov sib txuas ntawm synchronous sanitary inspection line, muab tso rau hauv lub tsheb kaw thiab rub tawm ntawm lub tsev tua tsiaj rau kev ua haujlwm.

(5) Cov viscera liab thiab cov viscera dawb ntawm cov kab tshuaj ntsuam xyuas synchronous tau txais kev ntxuav thiab tshuaj tua kab mob los ntawm dej txias-kub-txias.

7. By-product processing

(1) Tsim nyog cov viscera dawb nkag mus rau hauv chav ua haujlwm dawb viscera los ntawm cov viscera chute dawb, hliv cov ntsiab lus hauv plab hauv plab thiab cov hnyuv mus rau hauv lub tank xa cua, sau nrog cov cua compressed, thiab thauj cov khoom hauv plab los ntawm cov pa xa mus rau lub tank. slaughter Txog 50 meters sab nraum lub rhiav, lub tripe yog ntxuav los ntawm ib tug tripe ntxhua khaub ncaws. Muab cov hnyuv ntxuav thiab plab tso rau hauv qhov chaw txias los yog lub tsev khaws khoom tshiab.

(2) Cov viscera liab uas tsim nyog nkag mus rau hauv chav ua haujlwm liab viscera los ntawm cov visceral chute liab, ntxuav lub plawv, daim siab, thiab ntsws, thiab ntim lawv rau hauv qhov txias txias lossis lub tsev khaws khoom tshiab.

8. carcass acid excretion

(1) Muab cov khoom txiav thiab ntxuav cov menyuam yaj mus rau hauv cov kua qaub-tso tawm chav rau "tso tawm", uas yog ib feem tseem ceeb ntawm cov txheej txheem yaj txias txias.

(2) Qhov kub ntawm cov kua qaub tawm: 0-4 ℃, thiab cov kua qaub tawm lub sij hawm tsis pub tshaj 16 teev.

(3) Qhov siab ntawm cov kua qaub tawm khiav tsim los ntawm hauv pem teb ntawm chav tsev acid tsis tsawg dua 2200mm, qhov kev ncua deb: 600-800mm, thiab chav dej kua qaub tuaj yeem dai 5-8 tus yaj carcasses ib meter ntawm kev khiav.

9. Deboning thiab ntim

(1) Hanging deboning: thawb tus menyuam yaj carcass tom qab deacidification rau thaj tsam deboning, thiab dai tus menyuam yaj carcass ntawm cov kab ntau lawm. Cov neeg ua haujlwm deboning muab cov nqaij txiav loj rau ntawm cov khoom txiav thiab cia li xa mus rau cov neeg ua haujlwm txiav. Muaj cov neeg ua haujlwm faib cov nqaij rau hauv ntau qhov chaw.

(2) Txiav board deboning: thawb lub carcass ntawm yaj mus rau qhov deboning cheeb tsam tom qab deacidification, thiab tshem tawm cov yaj carcass tawm ntawm cov kab ntau lawm thiab muab tso rau hauv lub txiav board rau deboning.

(3) Tom qab cov nqaij txiav yog lub tshuab nqus tsev ntim, muab tso rau hauv lub tais khov thiab thawb mus rau hauv chav txias (-30 ℃) kom khov los yog mus rau cov khoom tiav chav txias (0-4 ℃) kom nws tshiab.

(4) Ntim cov khoom khov pallets thiab khaws cia rau hauv lub tub yees (-18 ℃).

(5) Kev tswj kub ntawm qhov deboning thiab segmentation chav: 10-15 ℃, kub tswj chav ntim: hauv qab 10 ℃.

Paub meej daim duab

Ua raws li kev ntseeg ntawm "Tsim cov khoom ntawm sab saum toj ntawm ntau yam thiab tsim cov phooj ywg nrog cov neeg niaj hnub no los ntawm thoob plaws lub ntiaj teb", peb ib txwm muab kev txaus siab ntawm cov neeg yuav khoom hauv thawj qhov chaw rau Tuam Tshoj Slaughtering Equipment Chaw tsim tshuaj paus / Halal Slaughter ntawm Tsiaj txhu thiab Nqaij qaib, Peb ua siab dawb cia siab tias yuav pauv thiab koom tes nrog koj. Cia peb txav mus rau pem hauv ntej ntawm tes thiab ua tiav qhov xwm txheej yeej-yeej.

Ua raws li kev ntseeg ntawm "Tsim cov khoom ntawm sab saum toj ntawm ntau yam thiab tsim cov phooj ywg nrog cov neeg niaj hnub no los ntawm thoob plaws lub ntiaj teb", peb ib txwm muab kev txaus siab ntawm cov neeg yuav khoom hauv thawj qhov chaw rau Tuam Tshoj Slaughtering Equipment Chaw tsim tshuaj paus / Halal Slaughter ntawm Tsiaj txhu thiab Nqaij qaib, Peb ua siab dawb cia siab tias yuav pauv thiab koom tes nrog koj. Cia peb txav mus rau pem hauv ntej ntawm tes thiab ua tiav qhov xwm txheej yeej-yeej.

Chaw tsim tshuaj paus ntawmTuam Tshoj Slaughter Equipment, Qaib Slaughter Machine Line, Nrog ze li ntawm 30 xyoo kev ua lag luam, peb muaj kev ntseeg siab hauv kev pabcuam zoo tshaj, zoo thiab xa khoom. Peb sov siab txais tos cov neeg siv khoom los ntawm thoob plaws lub ntiaj teb los koom tes nrog peb lub tuam txhab rau kev txhim kho.