Npua Slaughter Line Process

Pig Slaughter Line

Pig Slaughter Line

1.Cov txheej txheem ntawm npua dehairing kab

Noj qab nyob zoo npua nkag tuav cwj mem → Nres noj / haus rau 12-24h → Da dej ua ntej tua → Instantly stunning → shackling thiab lifting → tua → los ntshav (Lub sij hawm: 5min) → npua carcass ntxuav → Scalding → Dehairing → Trimming → Carcass lifting → Hair singeing → Ntxuav thiab nplawm → Pob ntseg trimming → Rectum sealing → Genitals txiav → Lub hauv siab qhib → Dawb viscera tshem tawm (Muab lub viscera dawb tso rau hauv lub tais ntawm lub viscera dawb quarantine conveyor rau kev tshuaj xyuas → ①②) → Trichinella spiralis tshuaj xyuas → Tshem tawm viscera liab Kev tshem tawm viscera (Lub viscera liab yog dai rau ntawm tus nuv ntawm lub viscera liab quarantine conveyor rau kev soj ntsuam → ②③) → Pre-head txiav → Spliting → Carcass thiab viscera synchronized quarantine → Tail txiav → taub hau txiav → Fore hoof cutting → Leaf Kev tshem tawm rog → Dawb carcass trimming → Nyhav → Ntxuav → Chilling (0-4 ℃) → Cov nqaij tshiab Chilled nqaij ntsaws ruaj ruaj

LOSSIS → Txiav rau hauv peb seem → Txiav nqaij → Nyhav thiab ntim → khov los yog khaws cia tshiab → tshem tawm lub tais ntim → Txias cia → Txiav nqaij rau muag.

① Tsim nyog cov viscera dawb nkag mus rau chav dawb viscera rau kev ua haujlwm. Lub plab cov ntsiab lus raug thauj mus rau hauv chav tsev khib nyiab txog 50 meters sab nraum lub rooj cob qhia los ntawm huab cua xa khoom.

② Cov pob txha tsis tsim nyog, liab thiab dawb viscera raug rub tawm ntawm kev tua tsiaj rau kev kho mob kub.

③ Tsim nyog viscera liab nkag mus rau hauv chav liab viscera rau kev ua.

2.Cov txheej txheem ntawm npua tev kab

Noj qab nyob zoo npua nkag tuav cwj mem → Nres noj / haus rau 12-24h → Da dej ua ntej tua → Instantly stunning → shackling thiab lifting → tua → los ntshav (Lub sij hawm: 5min) → npua carcass ntxuav → taub hau txiav → Unload tus npua mus rau hauv lub pre-peeling chaw nres tsheb → Hoof thiab Tail txiav (Xa mus rau lub taub hau thiab lub hoof processing room) → Pre-peeling → Peeling (Pigskin ib ntus cia chav tsev) → Carcass lifting → Trimming → Rectum sealing → Genitals cutting → Chest open → White viscera remove (Muab cov dawb viscera nyob rau hauv lub tais ntawm lub viscera dawb quarantine conveyor rau kev soj ntsuam → ①②) → Trichinella spiralis tshuaj xyuas → Pre red viscera tshem tawm → Liab viscera tshem tawm (Lub viscera liab yog dai rau ntawm tus nuv ntawm liab viscera quarantine conveyor → ②) Lub taub hau txiav → Spliting → Carcass thiab viscera synchronized quarantine → Tail txiav → Lub taub hau txiav → Fore hoof cutting → Hind hoof cutting → Leaf fat tshem tawm → Dawb carcass trimming → Nyhav → Ntxuav → Chilling (0-4 ℃) → Cov nqaij tshiab Chilled nqaij cov ntsaws ruaj ruaj

LOSSIS → Txiav rau hauv peb seem → Txiav nqaij → Nyhav thiab ntim → khov los yog khaws cia tshiab → tshem tawm lub tais ntim → Txias cia → Txiav nqaij rau muag.

① Tsim nyog cov viscera dawb nkag mus rau chav dawb viscera rau kev ua haujlwm. Lub plab cov ntsiab lus raug thauj mus rau hauv chav tsev khib nyiab txog 50 meters sab nraum lub rooj cob qhia los ntawm huab cua xa khoom.

② Cov pob txha tsis tsim nyog, liab thiab dawb viscera raug rub tawm ntawm kev tua tsiaj rau kev kho mob kub.

③ Tsim nyog viscera liab nkag mus rau hauv chav liab viscera rau kev ua.

Pig Dehairing Tshuab

Pig Peeling Kab

Npua Slaughter Process

tuav cwjmem tswj

(1) Ua ntej tus npua muaj sia nkag mus rau hauv cov cwj mem tuav hauv lub tsev tua tsiaj kom tshem tawm, yuav tsum tau txais daim ntawv pov thawj ntawm kev ua raws li lub koom haum saib xyuas kev tiv thaiv kab mob ntawm cov tsiaj, thiab yuav tsum tau saib xyuas lub tsheb, tsis pom qhov txawv txav. Unloading raug tso cai tom qab ua raws li daim ntawv pov thawj thiab cov khoom thauj.

(2) Tom qab unloading, quarantine tub ceev xwm yuav tsum saib xyuas kev noj qab haus huv ntawm cov npua nyob ib tug los ntawm ib tug, Raws li qhov tshwm sim ntawm kev soj ntsuam, pab pawg neeg thiab naj npawb nws.Cov npua noj qab nyob zoo tau raug tsav mus rau hauv cov cwj mem tuav kom so; Cov npua uas xav tias mob yog corralled mus rau hauv ib cheeb tsam cais, soj ntsuam txuas ntxiv; npua mob thiab neeg xiam oob qhab raug xa mus rau chav tua thaum muaj xwm ceev.

(3) Cov npua mob ntshav qab zib tom qab haus dej thiab so kom txaus, rov qab mus rau qhov qub tuaj yeem raug tsav mus rau hauv cov cwj mem tuav; Yog tias cov tsos mob tseem tsis zoo, xa mus rau chav tua tsiaj thaum muaj xwm ceev.

(4) Npua yuav tsum tua yuav tsum tsis pub noj thiab so rau 12-24 teev ua ntej tua.Nyob rau hauv thiaj li yuav tshem tawm qaug zog nyob rau hauv kev thauj mus los thiab rov qab ib tug physiological xeev. mus rau qhov chaw nyob ib leeg rau kev soj ntsuam.Kom muaj mob npua thiab xa mus rau chav tua ceev ceev, npua noj qab haus huv nres haus dej 3 teev ua ntej tua.

(5) Cov npua yuav tsum tau da dej ua ntej nkag mus rau hauv lub tsev tua tsiaj, ntxuav cov av thiab microbes tawm ntawm npua, tib lub sij hawm nws kuj yooj yim rau stunning, Tswj cov dej siab hauv da dej, tsis txhob ceev heev kom zam. tus npua overstress.

(6) Tom qab da dej, cov npua tau tsav mus rau hauv lub khw tua tsiaj los ntawm cov npua khiav, cov npua khiav feem ntau yog tsim los ua hom funnel.Thaum pib, txoj kev npua yuav tso cai rau ob mus rau plaub tus npua mus rau ntawm ib sab, maj mam. tsuas yog ib tus npua tuaj yeem xa mus, thiab ua rau tus npua tsis tuaj yeem tig rov qab, lub sijhawm no, qhov dav ntawm tus npua khiav yog tsim los ntawm 380-400mm.

Zoo kawg

(1) Stun yog ib qho tseem ceeb hauv kev tua npua, lub hom phiaj ntawm kev stun tam sim no yog ua kom tus npua tsis nco qab ib ntus thiab nyob rau hauv lub xeev comatose, thiaj li tua thiab los ntshav, ua kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm, txo kev siv zog, txhim kho kev ua haujlwm. ntau lawm efficiency, ua kom ib puag ncig ib ncig ntawm lub slaughterhouse nyob ntsiag to, thiab txhim kho cov nqaij zoo.

(2) Phau ntawv stunner feem ntau yog siv nyob rau hauv me me slaughterhouses nyob rau hauv tam sim no, cov neeg tsav tsheb yuav tsum hnav ntev roj hmab khau thiab hnab looj tes roj hmab kom tsis txhob muaj hluav taws xob poob siab ua ntej yuav siv cov cuab yeej, ua ntej stunning, ob lub electrodes ntawm stunner yuav tsum tau immersed nyob rau hauv saline nrog ib tug concentration ntawm 5% successively los txhim kho cov hluav taws xob conductivity, stunning voltage: 70-90v, sij hawm: 1-3s.

(3) Peb - taw tes tsis siv neeg stunning conveyor yog cov khoom siv hluav taws xob zoo tshaj plaws, cov npua nyob nkag mus rau hauv cov khoom siv ntawm lub tshuab zoo nkauj los ntawm cov npua khiav, txhawb nqa lub plab ntawm tus npua, plaub hoof dai hauv huab cua rau 1-2min tus me nyuam , tshem tawm qhov nro hauv npua, ua rau lub hlwb thiab lub siab zoo nyob rau hauv qhov xwm txheej uas tus npua tsis ntshai, lub sijhawm zoo nkauj: 1-3s, stunning voltage: 150-300v, stunning tam sim no: 1-3A, stunning zaus: 800hz

Txoj kev stun no tsis muaj ntshav stains thiab pob txha, thiab nws ncua kev poob ntawm PH tus nqi, zoo heev txhim kho cov nqaij npuas thiab tsiaj txhu zoo tib lub sijhawm.

Tua thiab los ntshav

(1) Kab rov tav los ntshav: tus npua stun swb mus rau kab rov tav los ntshav conveyor los ntawm chute, tua nrog rab riam, tom qab 1-2 feeb los ntshav, 90% ntawm tus npua cov ntshav ntws mus rau hauv lub tank sau cov ntshav, txoj kev tua no yog conducive mus sau thiab siv cov ntshav, nws kuj txhim kho lub peev xwm tua.Nws kuj yog ib tug zoo meej ua ke ntawm peb - taw tes stunning tshuab.

(2) Hanging handstand los ntshav: tus npua stunned tau chained mus rau ib qho ntawm nws hind ob txhais ceg, tus npua yog lifted rau hauv txoj kev tsheb ciav hlau ntawm cov tsis siv neeg los ntshav conveying kab los ntawm tus npua hoist los yog lub lifting ntaus ntawv ntawm tus npua los ntshav kab, thiab ces tua lub npua nrog riam.

(3) Txoj kev tsheb ciav hlau ntawm tus npua tsis siv neeg los ntshav kab yuav tsum tsis txhob qis dua 3400mm los ntawm hauv pem teb ntawm lub rooj cob qhia, cov txheej txheem tseem ceeb yuav tsum tau ua tiav ntawm txoj kab tsis siv neeg los ntshav: dai (tua), los ntshav, npua carcass ntxuav, txiav taub hau , lub sij hawm los ntshav feem ntau yog tsim los ua 5min.

Scalding thiab dehairing

(1) Npua scalding: unload tus npua los ntawm tus npua unloader mus rau scalding tank txais lub rooj, maj mam xaub lub cev npua rau hauv lub tank scalding, txoj kev ntawm scalding yog phau ntawv scalding thiab machinery scalding, dej kub feem ntau tswj ntawm 58- 62 ℃, dej kub siab dhau yuav ua rau npua lub cev dawb, cuam tshuam cov nyhuv dehairing.

Scalding lub sij hawm: 4-6min.A "skylight" yog tsim los ntws cov pa ncaj qha saum lub tank scalding.

● Sab saum toj kaw npua scalding qhov: npua lub cev yuav cia li xa mus rau hauv qhov scalding qhov los ntawm cov npua los ntshav los ntawm txoj kab nqes nqes, scalding nyob rau hauv lub kaw npua scalding tank rau 4-6min, lub siab pas nrig yuav tsum tau tsim los tuav lub npua nyob rau hauv tus txheej txheem ntawm conveying thiab scalding, tiv thaiv tus npua los ntawm floating.Tus npua tom qab scalding yuav cia li thauj tawm los ntawm lub nkhaus rail, hom scalding tank muaj zoo thaum tshav kub kub preservation nyhuv.

● Steam scalding tunnel system: dai tus npua tom qab los ntshav ntawm txoj kab tsis siv neeg los ntshav thiab nkag mus rau hauv qhov scalding qhov, txoj kev scalding no txo qis kev siv zog ntawm cov neeg ua haujlwm, txhim kho kev ua haujlwm, paub txog kev ua haujlwm ntawm cov npua scalding, thiab ntawm tib lub sij hawm zam qhov tsis zoo ntawm kev sib kis kab mob ntawm cov npua, ua rau cov nqaij ua kom huv.Qhov no yog qhov kev tshaj lij tshaj plaws, qhov zoo tshaj plaws daim ntawv ntawm npua scalding.

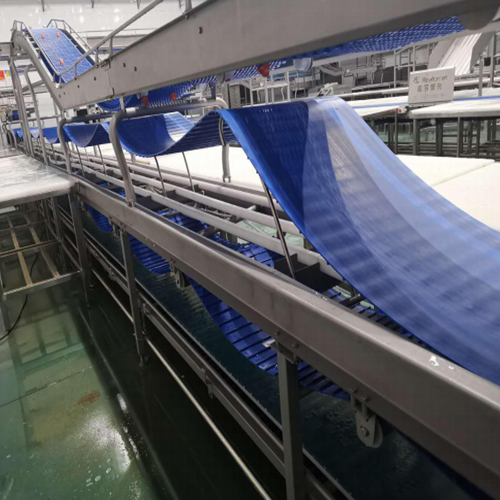

● Kab rov tav dehairing: txoj kev dehair no mas siv 100 qauv dehairing tshuab, 200 qauv mechanical (hydraulic) dehairing tshuab, 300 qauv mechanical (hydraulic) dehairing tshuab, ob chav ncej hydraulic dehairing tshuab.Lub tshuab dehairing siv lub rake kom tshem tawm cov npua scalded los ntawm lub tank scalding thiab cia li nkag mus rau hauv lub tshuab dehairing, dov ntawm cov chais loj thiab cov nplais ntawm cov paddles kom tshem tawm cov plaub hau npua, ces tus npua nkag mus rau trimming conveyor lossis dej huv tank rau trimming.

● U hom tsis siv neeg dehairing tshuab: daim ntawv no ntawm lub tshuab dehairing tuaj yeem siv ua ke nrog rau sab saum toj kaw scalding qhov los yog chav scalding qhov system, cov npua scalded nkag mus rau lub tshuab dehairing los ntawm txoj kab los ntshav los ntawm cov npua unloader, siv cov paddle mos thiab muab kauv txoj kev thawb. tawm tus npua los ntawm qhov kawg ntawm lub tshuab dehairing mus rau lwm qhov kawg, tom qab ntawd tus npua nkag mus rau trimming conveyor rau trimming.

Carcass processing

(1) Carcass processing station: carcass trimming, rectum sealing, qhov chaw mos txiav,

lub hauv siab qhib, dawb viscera tshem tawm, cais tawm ntawm trichinella spiralis, ua ntej liab viscera tshem tawm, liab viscera tshem tawm, sib cais, cais tawm, nplooj roj tshem tawm, thiab lwm yam,

tag nrho cov ua tiav ntawm cov carcass tsis siv neeg ua kab.Cov kev tsheb ciav hlau tsim ntawm npua carcass txheej txheem kab tsis qis dua 2400mm los ntawm hauv pem teb ntawm lub rooj cob qhia.

(2) Lub dehaired lossis dehided carcass yog nqa los ntawm carcass lifting tshuab mus rau txoj kev tsheb ciav hlau ntawm carcass tsis siv neeg conveying kab, Cov npua dehaired xav tau singeing thiab ntxuav; Tus npua dehided xav tau carcass trimming.

(3) Tom qab qhib lub hauv siab ntawm tus npua, tshem tawm cov viscera dawb ntawm tus npua lub hauv siab, uas yog cov hnyuv, tripe. Muab cov viscera dawb tso rau hauv lub tais ntawm cov viscera dawb quarantine conveyor rau kev tshuaj xyuas.

(4) Tshem tawm cov viscera liab, uas yog lub plawv, daim siab thiab lub ntsws.Hang lub viscera liab tshem tawm ntawm lub hooks ntawm liab viscera synchronous quarantine conveyor rau kev tshuaj xyuas.

(5) Faib cov nqaij npua hauv ib nrab siv hom siv los yog choj hom splitting pom raws tus npua tus txha nraub qaum, ntsug acceleration tshuab yuav tsum tau ntsia ncaj qha saum tus choj hom splitting saw.Small slaughterhouses siv reciprocating hom splitting saws.

(6) Tom qab dehaired npua splitting, tshem tawm pem hauv ntej hoof, rov qab hoof thiab npua tus Tsov tus tw, tshem tawm hoof thiab tus Tsov tus tw yog thauj los ntawm lub laub mus rau lub chav ua hauj lwm.

(7) Tshem cov ob lub raum thiab cov nplooj roj, tshem tawm lub raum thiab nplooj roj raug thauj los ntawm lub laub mus rau chav ua haujlwm.

(8) Pig carcass rau trimming, tom qab trimming, lub carcass nkag mus rau hauv lub khiav hluav taws xob ntsuas yuav tsum tau hnyav. Kev faib tawm thiab foob raws li qhov tshwm sim ntawm qhov hnyav.

Synchronized quarantine

(1) npua carcasses, dawb viscera thiab liab viscera yog xa mus rau qhov chaw soj ntsuam los ntawm pem teb mounted hom quarantine conveyor rau sampling thiab soj ntsuam.

(2) Lub cev tsis tsim nyog rau txim rau lub cev, dhau los ntawm kev hloov mus rau hauv qhov kev txiav txim siab ntawm lub tsheb ciav hlau, mus rau qhov thib ob cais tawm, pom tias muaj mob carcasses nkag mus rau hauv qhov kev txiav txim siab carcasses rail, tshem tawm cov neeg raug txim thiab muab tso rau hauv lub laub kaw, tom qab ntawd xa tawm ntawm lub rhiav slaughter. ua txheej txheem.

(3) Cov viscera dawb uas tsis tsim nyog yuav tsum tau muab tshem tawm ntawm lub tais ntawm cov khoom siv cais tawm, muab tso rau hauv lub laub kaw, tom qab ntawd xa tawm ntawm lub tshuab tua tsiaj los ua haujlwm.

(4) Cov viscera liab uas tsis tsim nyog yuav tsum tau muab tshem tawm ntawm lub tais ntawm cov khoom siv cais tawm, muab tso rau hauv lub laub kaw, tom qab ntawd xa tawm ntawm lub tshuab tua tsiaj los ua haujlwm.

(5) Cov viscera liab thiab cov viscera dawb rau hauv pem teb mounted synchronous quarantine conveyor tau txais kev ntxuav thiab ua kom tsis muaj menyuam los ntawm dej txias-kub-txias.

By-product processing

(1) Cov viscera dawb uas tsim nyog nkag mus rau hauv chav ua haujlwm dawb viscera los ntawm cov viscera chute dawb, ncuav cov ntsiab lus ntawm lub plab thiab cov hnyuv mus rau hauv cov huab cua xa tank, Lub plab cov ntsiab lus yuav raug thauj mus rau li 50 meters sab nraum lub slaughtering Rhiav los ntawm huab cua. conveying yeeb nkab nrog compressed cua.Pig tripe muaj lub tripe tshuab ntxhua khaub ncaws. Kev txheeb xyuas thiab ntim cov hnyuv thiab lub plab uas huv si rau hauv tub yees los yog cia tshiab.

(2) Cov viscera liab uas tsim nyog nkag mus rau hauv chav ua haujlwm liab viscera los ntawm cov viscera chute liab, ntxuav lub plawv, siab thiab ntsws, ces muab faib thiab ntim rau hauv tub yees lossis cia tshiab.

1.Dawb carcass chilling

(1) Cov nqaij npua tom qab txiav thiab ntxuav, nkag mus rau hauv chav txias kom txias, qhov no yog ib qho tseem ceeb ntawm npua nqaij txias txiav tshuab.

(2) Txhawm rau ua kom lub sijhawm ua kom sov lub cev dawb, lub tshuab cua txias ceev ntawm lub cev yog tsim ua ntej lub cev nkag mus rau hauv chav txias txias, qhov kub ntawm chav txias txias yog tsim los ntawm -20 ℃, thiab lub sijhawm txias txias. yog tsim raws li 90 feeb.

(3) Qhov kub ntawm chav txias: 0-4 ℃, lub sijhawm txias tsis tshaj 16 teev.

(4) Lub chilling rail tsim tsis qis dua 2400mm los ntawm qhov siab ntawm chav chilling pem teb, rail spacing: 800mm, ib meter rail yuav dai 3 taub hau npua carcass nyob rau hauv lub chilling chav.

Txiav thiab ntim

(1) Cov carcass dawb tom qab txias tau raug tshem tawm ntawm txoj kev tsheb ciav hlau los ntawm cov nqaij unloading tshuab, siv cov segmented pom los faib txhua daim nqaij npua rau hauv 3-4 ntu, siv lub conveyor, tsis siv neeg hloov mus rau qhov chaw ntawm cov neeg ua haujlwm txiav, tom qab ntawd cov nqaij yog txiav rau hauv cov nqaij los ntawm cov neeg ua haujlwm txiav.

(2) Tom qab lub tshuab nqus tsev ntim ntawm cov nqaij ntuag, muab tso rau hauv lub tais khov los ntawm lub tawb nqa khoom thiab thawb nws mus rau chav txias (-30 ℃) lossis mus rau cov khoom tiav chav txias (0-4 ℃) rau khaws cia tshiab.

(3) Ntim cov khoom khov rau hauv lub thawv thiab khaws cia rau hauv lub tub yees (-18 ℃)

(4) Kev tswj kub ntawm lub pob txha thiab txiav chav: 10-15 ℃, kev tswj kub ntawm chav ntim: hauv qab 10 ℃.

Kuv tau cim qhov sib txawv ntawm ob kab tua kab xiav. Nws tsis muaj teeb meem txog qhov loj ntawm lub tsev tua npua, qhov tsim ntawm cov npua tua kab yuav tsum tau ua raws li cov yam ntxwv xws li qhov loj, qhov teeb tsa thiab qhov ntim txhua hnub ntawm lub tsev tua tsiaj. Kev txiav txim siab txog ntau yam (xws li kev nqis peev, tus naj npawb ntawm cov neeg ua haujlwm, qib slaughter, npaj ntim ntim, thiab lwm yam) los yuav cov cuab yeej tua tsiaj. Cov npua niaj hnub tua kab yog maj mam txhim kho mus rau automation, tab sis qhov siab dua qib ntawm automation kuj txhais tau tias tus nqi ntau dua ntawm cov khoom siv slaughter, tom qab cov nqi zog yuav tsawg dua. Qhov haum yog qhov zoo tshaj plaws, tsis yog qib siab ntawm automation yog qhov zoo tshaj plaws.

Paub meej daim duab